The Art of Proportional Control: Enhancing Precision with Hydraulic Valves

Hydraulic get a grip on valves are integral parts in hydraulic programs, helping as the key regulators of substance movement, pressure, and direction. These valves play a crucial position in a wide selection of programs, from commercial equipment and structure equipment to aerospace and automotive systems. The elementary concept behind hydraulic get a grip on valves is based on their ability to handle the flow of hydraulic water in just a program, permitting accurate get a handle on and adjustment of varied components.

One of the major operates of hydraulic get a grip on valves is always to regulate the force within a hydraulic system. Force get a handle on valves, such as aid valves, make certain that the pressure stays within safe operating limits, blocking possible damage to painful and sensitive components. That is particularly crucial in applications wherever sustaining a particular stress level is important for optimum efficiency and safety.

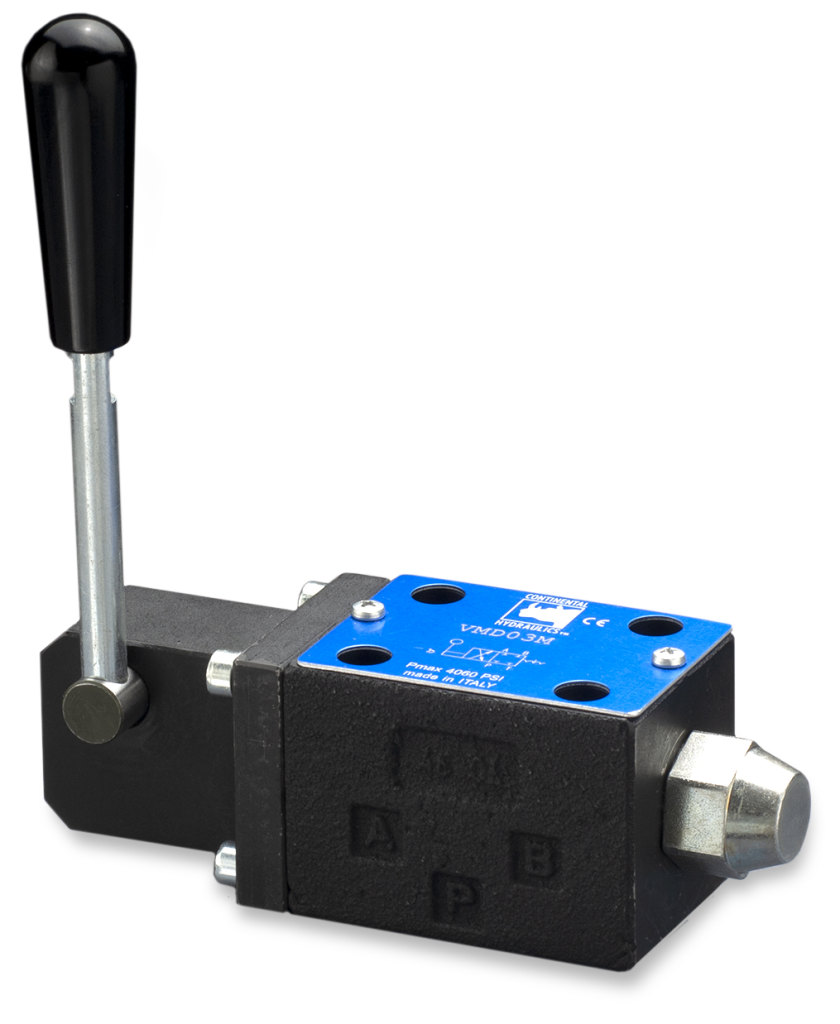

Online get a handle on valves are another crucial group of hydraulic get a handle on valves. These valves establish the way of fluid flow within the machine, permitting the managed action of hydraulic actuators. Whether it’s the extension or retraction of a hydraulic tube or the turn of a engine, directional get a grip on valves govern the routes through which hydraulic fluid flows, dictating the action of the related machinery.

Hydraulic control valves are made with many different control systems, including information, technical, and electro-hydraulic. Information valves permit hands-on get a handle on, physical valves respond to external forces or physical inputs, and electro-hydraulic valves leverage electrical signals for specific and automatic control. That range in control possibilities makes hydraulic techniques versatile to different functional demands and individual preferences.

Performance is just a critical factor in hydraulic programs, and hydraulic control valves play a crucial role in optimizing performance. Proportional get a handle on valves, for example, enable fine-tuned modifications to water movement charges, permitting specific control over the speed and force of hydraulic actuators. This level of get a handle on improves overall process performance, reducing power spend and ensuring optimal operation.

As well as their primary functions, hydraulic control valves donate to process safety. Force comfort valves become fail-safes, guarding the machine from overpressure and possible damage. The open character of the valves guarantees that, in the case of a force spike, hydraulic liquid is diverted properly, avoiding catastrophic failures and safeguarding equally the apparatus and personnel.

The maintenance of hydraulic get a grip on valves is vital for maintained process performance. Typical inspections, washing, and lubrication are essential to stop use and split, escapes, and other issues that may bargain the operation of the valves. Regular maintenance not just extends the lifetime of the valves but also assures the reliability of the whole hydraulic system.

Creativity in hydraulic get a grip on device engineering remains to advance, with the integration of electric and intelligent technologies. Digital get a handle on models (ECUs) allow specific and programmable get a grip on over hydraulic techniques, starting techniques for automation, distant monitoring, and predictive maintenance. As industries shift towards Business 4.0, the position of clever hydraulic control valves becomes increasingly critical in creating hydraulic control valves and sensible hydraulic systems.

In conclusion, hydraulic get a handle on valves are the unsung people of hydraulic programs, giving the necessary get a handle on and regulation for the efficient operation of numerous machinery and equipment. Their flexibility, precision, and share to system security make them crucial in industries where hydraulic energy is harnessed for an array of applications. As technology remains to improve, hydraulic get a handle on valves will likely enjoy a far more innovative position in surrounding the future of hydraulic methods across varied sectors.